Not all malt concentrates are made

equal.

Malt Concentrate is Malt Concentrate is Malt Concentrate….

In the beginning there was Blue Ribbon Malt. You could find it

in the baking section of the grocery store. It had a myriad of uses,

including making beer. This being the 1920’s, with alcohol

production/consumption in the US being illegal, the directions on

the label were quite coy. To paraphrase… “Do not do

this, then that, then this other thing. If you do, it will produce

beer, and that would be illegal”. While it was a good all-purpose

malt concentrate, used in baking, chocolate malts, candy-making

and yes, beer making, it was not designed especially for beermaking

and did not make really good beer. But then, neither is about 98%

of all the malt concentrate produced in the world today, including

most of the malt concentrates sold for beermaking purposes.

There is a world-wide commodity market for malt concentrates, and

most malt concentrates, including most of the malt concentrates

used in making various beer kits, are made in factories designed

to produce commodity food products. Malt concentrates are used in

a wide array of products, including edible foods like bagels, candy,

powdered drink mixes, vitamins and breakfast cereals (it is sprayed

on corn flakes to make frosted flakes). It is also used in making

pet food. As a percentage, a very small amount of the malt concentrate

made in the world is used to make beer. And an even smaller percentage

is actually produced with beermaking in mind. This is an important

distinction.

Good beer making requires using products that are specifically

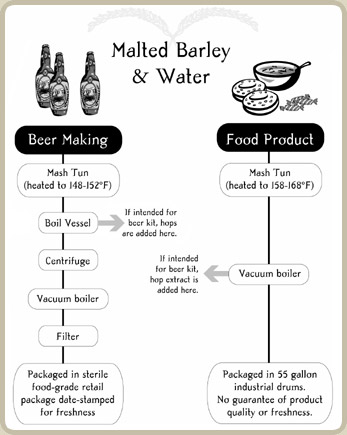

designed to make beer. Let’s walk through the process of malt

concentrate production to see how different processes effect the

finished product.

The major differences between the two approaches involves how

the malted barley is heated at the beginning of the process and

how the malt concentrate is handled after the heating process.

Temperature is important in brewing because the types and percentages

of fermentable or non-fermentable sugars produced are dependent

upon the temperature in the mash tun. A temperature of 148-152’F

ensures production of the types of fermentable sugars that make

for a well balanced, good tasting beer. This process also takes

longer and requires greater skill. Companies buying malt concentrate

to use in bagels or pet food don’t care about the levels of

fermentable sugars (after all, why would they?). Consequently, malt

factories whose primary focus is supplying the food industry opt

for the faster, easier mash tun regime of 158-164’F. Fine

for corn flakes…not as good for beer.

The food industry also does not have to concern itself with particulate

matter (uncoagulated proteins and the like) in the malt concentrate.

So, malt concentrate factories forgo the boil/centrifuge/filtering.

These processes are necessary if your intention is to make a good

quality beer with nice color and clarity.

Finally, because beermaking is such a small part of the overall

business of most malt concentrate producers, they have not, and

are not likely to, invest in equipment necessary to actually make

beer. Consequently, if they are producing a “beer kit”,

instead of investing in boil vessels and hop storage facilities,

they will simply add barrels of hop extract to the malt concentrate

prior to packaging.

So, how are The Coopers Brewery malt concentrates and beer kits

different? The Coopers Brewery is first and foremost a brewery.

We make beer. And when we aren’t making beer, we make products

for making beer. We have four Master Brewers (an actual legal designation

in Australia) on staff who oversee the process. The care and processes

that go into producing Coopers homebrewing products are the same

that go into the beers that renowned British beer and spirits critic

Michael Jackson praises for “their heartiness and uncompromising

honesty”.

Malt concentrate is not malt concentrate. If you don’t know

exactly what you are getting, it probably was not intended for beer

making. Use Coopers Brewery homebrewing products and be sure you

are using products by brewers, for brewers.

|